All Cable Sizes and Connector Types Accommodated

Cast Molded Parts Capabilities

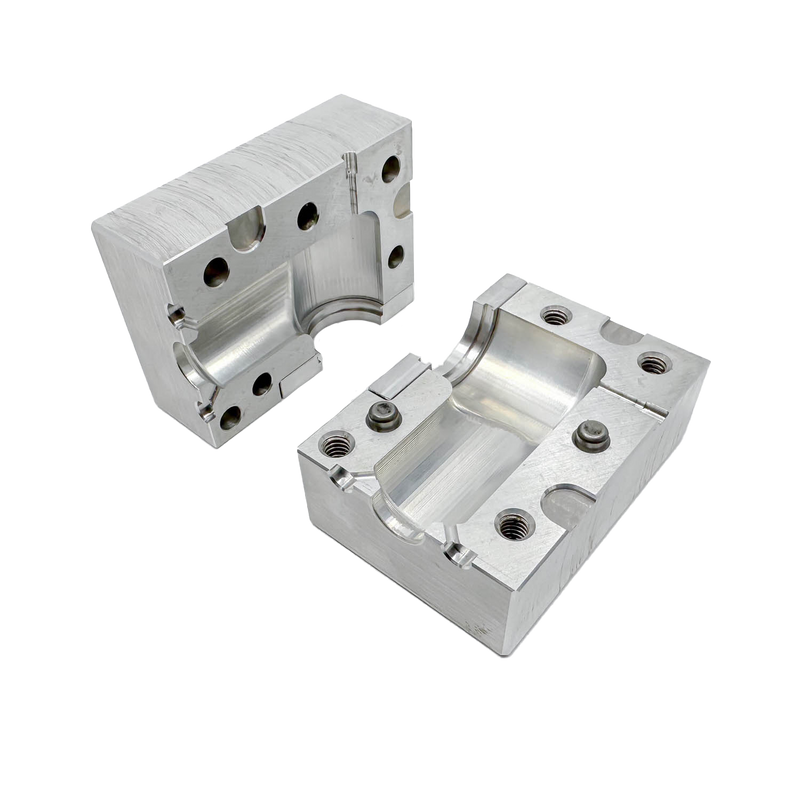

In-house Mold Machining

Large Material Capacity

Different Types of Overmolding

In-House Support Operations

Overmolding

CDM’s 3,000 square-foot Turnersville, NJ, machine shop supports the overmolding program by providing molds and specialty components to make the entire process seamless to customers.

-

Overmolding

- Provides a complete, seamless seal at the cable/connector junction

- Provides an effective strain relief

- Unlimited size, shape and color availability

- Overmold material used is specific to the application

- American made in-house at Turnersville, NJ under 100% quality control

- Possible mold or prototype costs

-

Shrink Boots

- Moisture and dust resistant, but not a true seal between the cable and connector

- Shouldn't be used as a strain relief

- Off-the-shelf sizes and shapes only, no color options

- Very limited choice of materials

- Mass produced and imported

- Budget-friendly